Our Advantages

Exceed customer expectations, serve customers with professionalism and win trust with integrity

No MOQ,Custom development is available

More favorable production solutions

Quality of delivery with 99% pass rate

Over 70% of peer-to-peer plant configurations

20+ years of professional technical support

On-Time Shipping

provide complete solutions according to functional requirements to ensure the smooth implementation of product functions and meet user needs.

management systems, monitoring systems and other multi-industry software / system development, for enterprises to turn information technology digital transformation construction to provide full production services.

Provide a series of solutions and implementation services including forklift safety, automobile safety, vehicle management, etc., to help enterprises optimize safety hazards, enhance operational quality and improve asset management

Our Service

Years of Experience

Professional Engineers

Cover Countries

sq.m PCB Capacity

Guangzhou Sabo Electronic Technology Co., Ltd. specializes in automotive electronics manufacturing services.

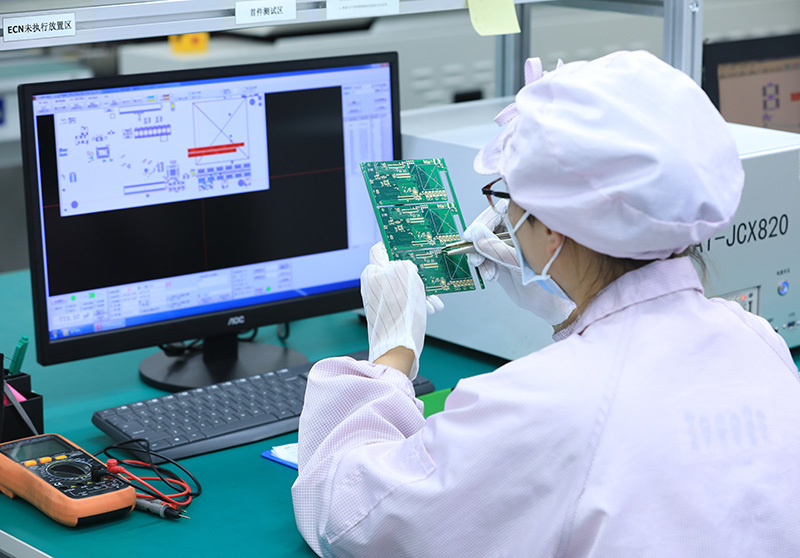

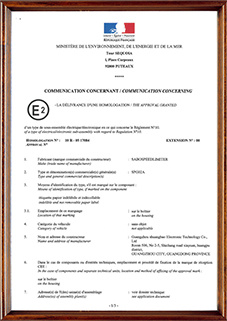

Sabo was established in 2010 with 100+ employees and 30,000 square meters of production and office space. We can provide one-stop service from PCB manufacturing, PCB assembly, component sourcing, programming, testing, conformal coating and housing assembly. With over 20+ years of successful experience in the global EMS market, our PCB production capacity can reach 30,000 square meters per month and our EMS assembly capacity can reach 15,000,000 components per month. Product quality has passed many system certifications such as ISO9001, ECE, and EU CE.

One-stop service

01

Quick turn prototypes

02

PCB Manufacturing

03

Components sourcing

04

Functional testing

05

Enclosure assembly

06

Software uploading

07

Customized packaging

08

SMT & Through holes assembl

PCB MANUFACTURING

Quick turn prototype & mass production

Design for Manufacturing(DFM) Checking

Laser-drilled microvias, via-in-pad

MOQ 1 piece

up to 40 layers, IPC Class 3 Standard

TARGET MARKET Proportion of worldregions

CUSTOMER VISITS

Service Process

Service quotation

Sample processing

Signing contract

Material procurement

Production processing

Testing inspection

Packaging shipping

Regular follow-up

Certificate display

news

30

2025-03

Understanding Forklift Driver Off-Position Alarms: Ensuring Safety in the Automotive Industry

25

2025-03

The Importance of Off-Position Alarm for Forklift Operators: Enhancing Safety and Efficiency

20

2025-03

Understanding the Importance of Forklift Driver Off-Position Alarms